About

The Subtrench Group is a dynamic leader in providing groundbreaking underwater trenching technology and services worldwide and combines companies and employees with over 3 decades of experience in subsea equipment design, fabrication, and operation.

Subtrench Group’s objective is to provide safe, reliable, environmentally friendly, cost efficient, minimum risk, innovative umbilical, cable, flexible and pipeline trenching in the most effective way to support our trenching clients.

SERVICES

The Subtrench Group has extensive capability to successfully enable it to readily and competently perform all aspects of trenching work. The capability covers all aspects of pipeline and stiff flexible and stiff umbilical trenching; cable, flexibles and umbilical trenching; remedial trenching of pipelines, cables, flexibles and umbilicals trenching. The Subtrench Group is also involved in Deep Sea Mining spreads.

Trenching Project Management, Design & Engineering

- Management of all aspects of a Project including schedules, designs, engineering, operations, commercial, etc.

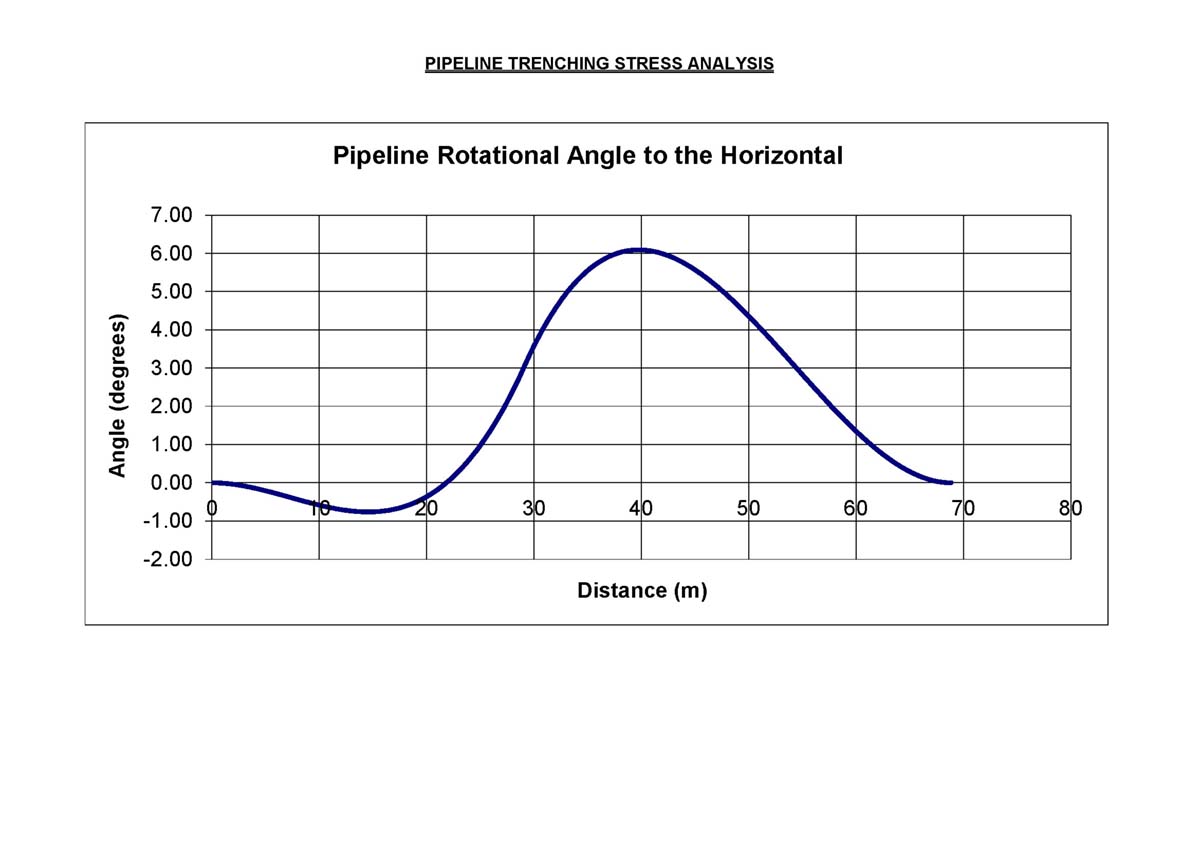

- Performing all necessary trenching engineering ranging from risk analysis through to pipeline trenching stress analysis.

- Developing procedures and methodologies for engineering, fabrication, operations and mobilization / demobilization to suit the individual and differing needs of each project.

- Engineering, setup and mobilizing of vessels for trenching operations.

- Achieving trenching parameters including trench depth, trenching stresses, out of vertical straightness tolerances, transitions, span corrections, high point corrections, etc.

- Defining and performing associated logistical requirements.

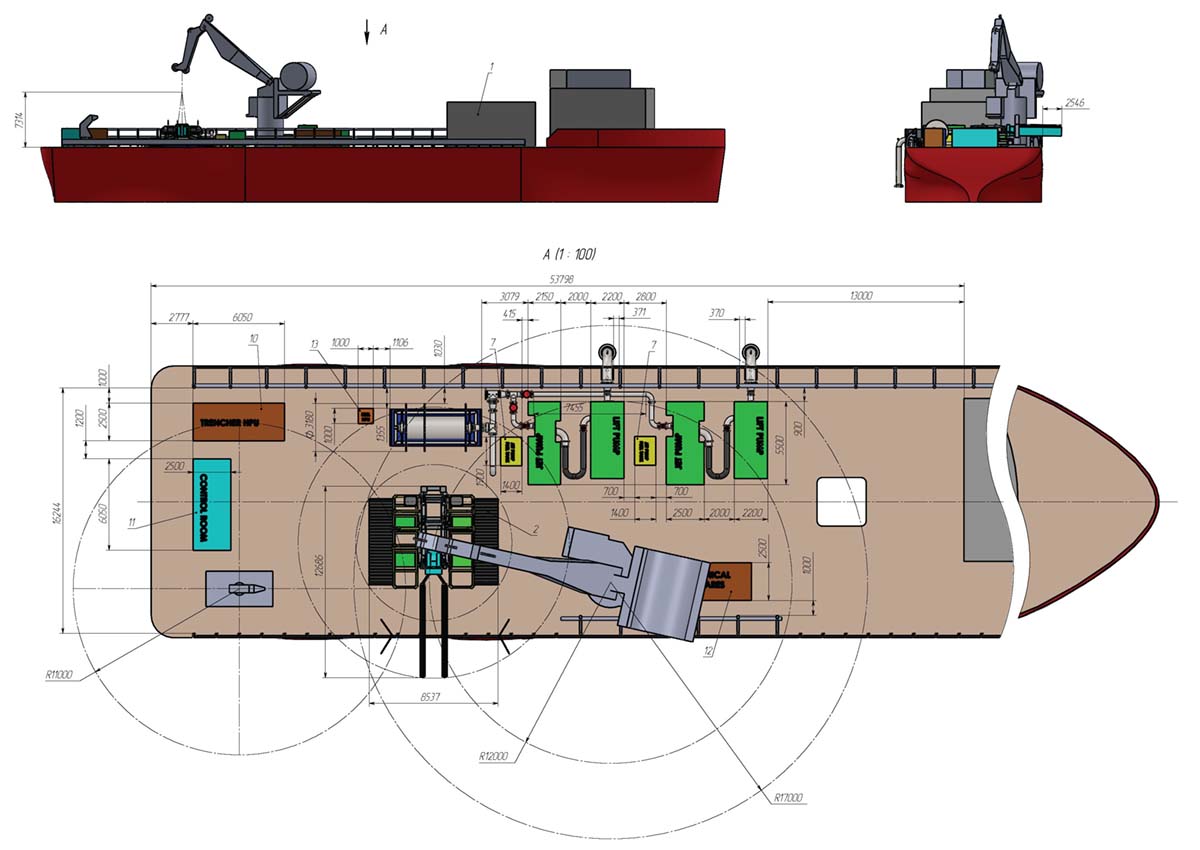

Typical Trenching Spread Vessel Layout Planning

Pipeline Trenching Stress Analysis

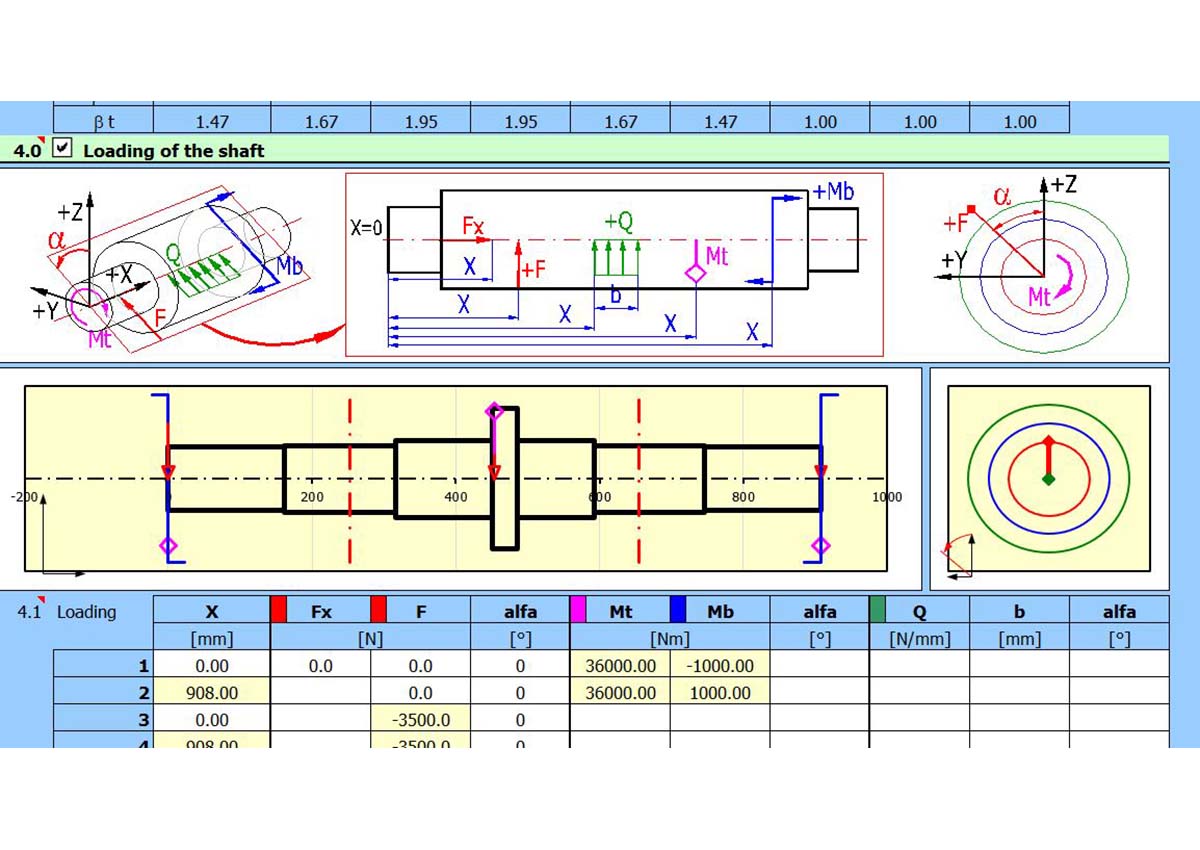

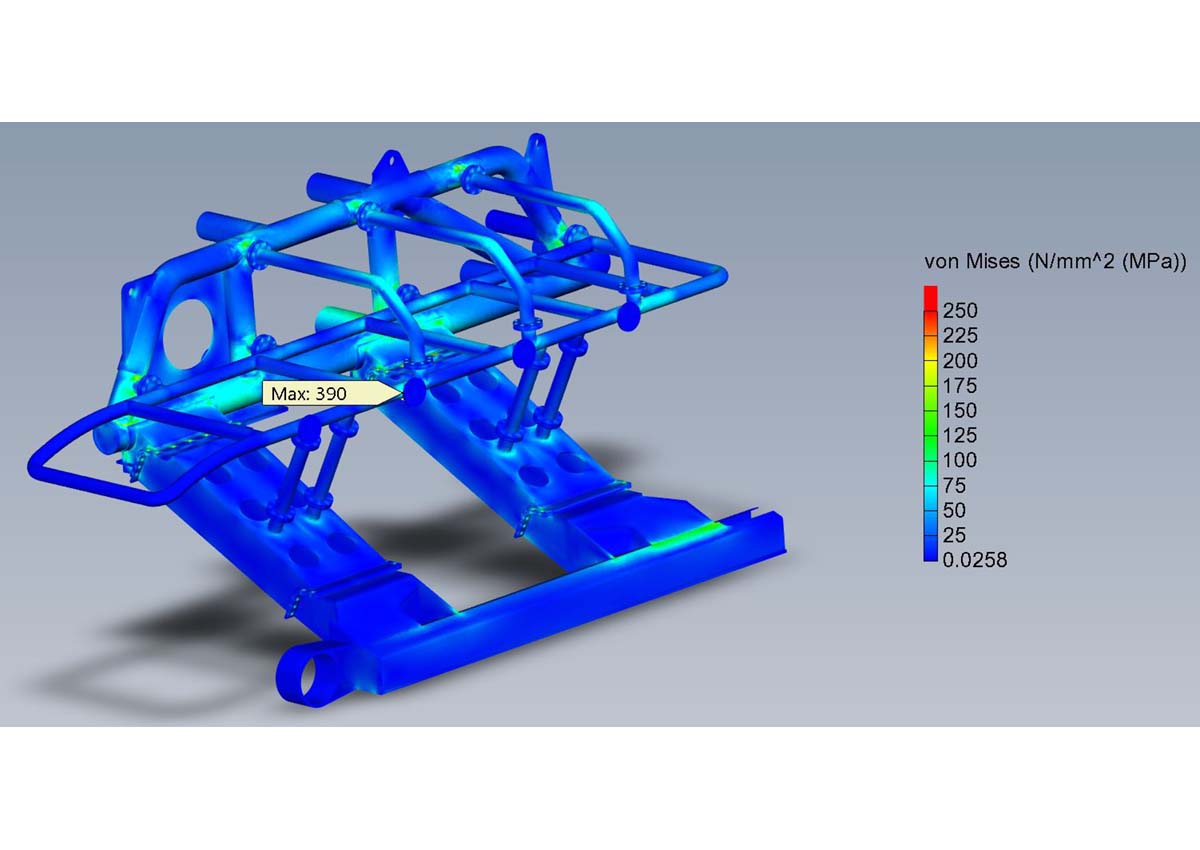

Subsea Equipment Design, Fabrication & Operation

- Equipment covering Tracked Machines, ROPs, Sleds, Mass Flow and Vertical Injectors.

- Trenching processes covering Jetting with and without transport, Liquefaction, Mechanical Cutting, Mass Flow and Eduction.

- Designs for new build and associated operational and marine requirements for cable, pipeline and umbilical trenching.

- Modification, enhancement and adaptation of existing machines and mechanisms for specific projects.

- Fabrication, testing and QA of new build, modification and enhancements trenching machines and associated equipment.

- Allowing for environments ranging from Arctic to Equatorial.

- Covering water depths ranging from above the shore water line to 500 m.

Chain Cutter Drive Shaft Design

Trenching Machine Frame Finite Element Analysis

Trenching Project Execution

- Provision of spreads and operations for a wide range of soils and water depths and in environments ranging from the Arctic to the Tropics.

- Operations from barges and pontoon barges with trenching from above the water line through inter tidal through very shallow to deep waters.

- Operations from DP vessels from shallow to deep waters.

- Providing diverless operations.

Pipeline Trenching Spread for Very Shallow Water Operation

Typical Shore Crossing with Trenching From Above the Water Line

QHSE

The principals and personnel of Subtrench are committed to performing all work to the highest level of safety, not only for the personnel involved in the work but also for the pipeline, cable, flexible or umbilical being trenched as well as protection of the local environment through the use of careful Planning and Preparation, Risk Analysis, Job Safety Analysis (JSA), Tool Box Talks and the use of appropriate Operating Methodologies and Experienced Personnel.

Typical Safety Induction and Briefing

Research & Development

Subtrench has performed extensive R&D in order to provide state of the art trenching equipment and operational methodologies to minimise the risks whilst maximising the reliability and performance in the field. Scale model testing and full size equipment testing has been performed as well as various studies and research.

R&D has covered:

- Jetting performance in various soils including actual field trenching performance;

- Mechanical cutter performance in various soils including actual field trenching performance;

- Trenching tool development and performance with Professor Cees van Rhee of the world-renowned Delft University in the Netherlands;

- Development of proprietary trenching tools;

- Performance of tracked vehicles under the water;

- Detailed analysis of all the various types of lowering processes covering ploughing, jetting without transport, jetting with transport, mechanical cutting, mass flow and eduction and their suitability for different soils and the different trenching requirements for pipelines, cables, flexibles and umbilicals;

- Detailed analysis of the various types of equipment to deliver the trenching processes including free flying, ride on the pipe, sled, tracked, plough and mass flow machines and their suitability for different soils and the different trenching requirements for pipelines, cables, flexibles and umbilicals;

- Detailed analysis of a short listed fifteen recommended trenching machine features covering safety through to support vessels through to the environment.

Scale Model Testing of Jet Nozzle Patterns and Eduction Techniques

Full Scale Jet and Trench Spoil Removal Testing

Full Scale Jet Sword Pattern Testing

Full Scale Chain Cutter Testing

EQUIPMENT SPREADS

The executive team have successfully developed or in the process of developing the following trenching spreads:

- Subtrench Eleven, in development, a new build surface feed hydraulic track driven subsea pipeline, cable, flexible and umbilical trenching machine with mechanical cutter and water jet trenching.

- Subtrench Ten, in development, a design prototype, hydraulic track driven, subsea pipeline, cable, flexible and umbilical trenching machine with mechanical cutter and water jet trenching.

- Subtrench Nine, an electro/ hydraulic, concept 150 Tonne machine capable of trenching to depths of 2m to 6m in soils ranging from sands through rock with chain cutters, barrel cutters and jet swords. For operation in waters impacted by iceberg keel movement through the seabed. Suitable for pipelines and cables.

- Subtrench Eight, a specialist subsea machine.

- Subtrench Seven, electro / hydraulic on bottom feed, hydraulic track driven, subsea pipeline, cable, flexible and umbilical trenching machine with interchangeable mechanical cutter and water jet trenching.

- Subtrench Six, a surface feed, hydraulic track driven, subsea pipeline and stiff flexible and umbilical trenching machine with interchangeable mechanical cutters and water jet trenching.

- Subtrench Five, a surface feed, multi pass, roll on the pipe (ROP) trenching machine.

- Subtrench Four, an electro hydraulic on bottom feed, hydraulic track driven, subsea bulldozer with an extendable jetting arm.

- Subtrench Three, a specialist subsea machine.

- Subtrench Two, an electro / hydraulic on bottom feed, hydraulic track driven, subsea cable, flexible and umbilical trenching machine with interchangeable trenching tools.

- Subtrench One, a surface feed, hydraulic track driven, subsea pipeline and stiff flexible and umbilical trenching machine with mechanical cutters and water jet trenching.

- Three hydraulic track driven, subsea cable and small pipeline/ umbilical mechanical cutter trenching machines.

- Seven uni-directional and bi-directional Roll on the Pipe (ROP) subsea pipeline jetting machines.

- A subsea bulldozer used to excavate and prepare the seabed.

- Three shallow draft pontoon trenching barges.

- Three hydraulic power pack and control modules.

- Power units and control cabins for operation of submersible trenching machines.

- Low- and high-pressure pump units, hydraulic power packs and systems, heave compensators, constant tension winch systems, low- and high-pressure hose reels, clump weight and pull bar systems, compressed air systems, hose bundle systems and pressure piping systems.

Subtrench One Pipeline Trencher

Subtrench Two Cable Trencher

Subtrench Four Subsea Bulldozer/ Excavator

Subtrench Five Central Frame

Subtrench Six

Subtrench Seven

EXPERIENCE

The Subtrench Group designs, builds and operates their own equipment. The Subtrench Group has also provided specialized designs for various Client’s internal use. The Subtrench Group has combined their significant offshore and subsea trenching experience together with detailed R&D, including model and full-size equipment testing, in order to provide state of the art trenching equipment and operational methodologies suitable for the many varied trenching project requirements encountered.

The Subtrench Group is also working on Deep Sea Mining spreads.

In particular, the Subtrench Group has sound and proven expertise and operational experience in the following areas:

- Pipeline and stiff flexible and umbilical trenching;

- Cable, flexibles and umbilical trenching;

- Remedial trenching of pipelines, cables, flexibles and umbilicals;

- Achieving trenching parameters including trench depth, trenching stresses, out of vertical straightness tolerances, transitions, span corrections, high point corrections, etc;

- Performing all necessary trenching project management and engineering ranging from risk analysis through to pipeline trenching stress analysis;

- Developing procedures and methodologies for engineering, fabrication, operations and mobilisation / demobilisation to suit the individual and differing needs of each project;

- Engineering, setup and mobilising vessels for trenching operations;

- Operations from barges and pontoon barges with trenching from above the water line through inter tidal through very shallow to deep waters;

- Operations from DP vessels from shallow to deep waters;

- Providing diverless operations.

Past projects have included trenching shore crossings, shore approaches, near shore and deeper waters throughout the world. The work has been carried out from Barges, Pontoons and DP vessels. Soils trenched have ranged from sands and silts through soft and hard clays with low, medium and high pressure water jetting and combination mechanical cutter/ water jet systems; and also calcarenite and rock using mechanical cutters. Site conditions have ranged from mild to extreme and have covered from the Arctic to the Tropics.

Pipelines have ranged from 6 inch to 42 inch nominal size and cables from 32mm fibre optic to 210mm OD double armoured power cables. Some pipelines have been trenched to very stringent vertical out of straightness tolerances to account for upheaval buckling. Large diameter (210mm OD) power cables have been trenched to more than 3.3 meters on a single pass. Pipeline trench depths have been to 5 meters with multipass.

Past projects which have been performed by; or which the Subtrench Group team has participated in the development and operation of; or a Subtrench Group designed equipment spread has been used for include:

- Luchterdwinen Offshore Wind Farm, North Sea (25km; export power cable; 3.3m & 1.5m trench depths; 0 to 25m water depth; sands and clays; jetting)

- ExxonMobil Pilton Bay Crossing Project, Russia (2.2km; 506mm OD pipeline; 1.8m trench depth; 1 to 5m water depth; sands with clays; jetting)

- ExxonMobil Tatar Strait Crossing Project, Russia (18km; 762mm OD pipeline; 2.5m trench depth; 0 to 25m water depth; dense sands, clays, silts, cobbles; chain cuter and jetting)

- Alpha Ventus Windfarm Project, Offshore Germany (export cable; 3.3m trench depth; 0 to 12m water depth; hard clays with stones; chain cutter)

- Q7 Windfarm Project, Offshore Holland (27km; export power cable; 3.3m & 1.5m trench depth; above waterline to 18m water depth; sands and clays; jetting)

- Total Nubi River Project, Indonesia (pipeline)

- Shell Goldeneye Project, Scotland (pipeline)

- Petrobras Guanabara Bay Project, Brasil (pipeline)

- Total Tunu 8 Project, Indonesia (pipeline)

- Esso Bream B Project, Australia (pipeline)

- Duke Energy Project, Australia (umbilical)

- Cabot Pipelines Project, Malaysia (pipeline)

- Cantarell Nitrogen Project, Mexico (pipeline)

- Total Tunu 6 Project, Indonesia (pipeline)

- Petrobras Marlin Sul/ Roncador, Brasil (pipeline)

- Total Peciko 42” River Crossing Project, Indonesia (pipeline)

- Total 16” Pipeline Repair Project, Indonesia (pipeline)

- Peciko 24” Shore Crossing Project, Indonesia (pipeline)

- Shell Terminal Project, Sri Lanka (pipeline)

- Esso Blackback Project, Australia (umbilical)

- IPCL Effluent Outfall Project, India (pipeline)

- CNOOC Pinghu Project, China (pipeline)

- Sabah Gas Pipeline Project, Malaysia (pipeline)

- Langkawi Island Water Supply Pipeline Project, Malaysia (pipeline)

- ONGC HRG HX/HY Pipelines, India (pipeline)

- ONGC B173 – A Pipeline Project, India (pipeline)

- and others (cables)

Trenching in Cemented Sands

Cable Shore Crossing

Subtrench Seven Control Panel

Cable Trenching

Cable Trenching with Chain Cutter Mode

Subtrench Two Control Room

Contact

USA

3363 NE 163 Street,

North Miami Beach,

FL 33160, USA

info@subtrenchglobal.com

Tel: +1 646 220 2201

Australia

C/O 13 North Concourse,

Beaumaris, 3193,

Victoria, Australia

info@subtrench.com

Tel: +61 (0) 400 922188